1.Description

A wet alarm valve is a one-way valve that only allows water to flow into the wet system and drive the associated components to alarm at a specified pressure flow;

The retarder is applied to the wet alarm valve device to prevent false alarms due to fluctuations in water supply pressure and leakage of the alarm valve;

The water motor alarm is a water-driven all-weather sound alarm facility that works without sparks and can be used in explosion-proof places. The hydraulic alarm bell is composed of an aluminum alloy body, an aluminum alloy impeller, an aluminum alloy bell shell, a copper alloy nozzle and a copper alloy bushing. No maintenance and long service life.

The wet alarm valve device and the pressure switch, water flow indicator, sprinkler, signal butterfly valve, end water test device, spray pump and the like constitute a wet automatic sprinkler system, which is the most widely used automatic sprinkler system.

Product standard: GB5135.2 "Automatic sprinkler system Part 2: Wet alarm valve, retarder, hydraulic bell"

Design Specification: GB50084 "Design Specification for Automatic Sprinkler System"

Acceptance specification: GB50261 "Code for construction and acceptance of automatic sprinkler system"

2.Working principle

When the wet alarm valve is in the servo state, the system side and the water supply side are filled with pressure water for a long time. When the upper and lower pressures generate microwave motion, the triangular valve core on the flap is adjusted to keep the upper and lower pressures consistent. When a fire occurs in the protected area, the ambient temperature rises to cause the sprinkler to spray water, and the pressure on the system side decreases with the pressure on the water supply side, which is greater than the pressure limit of the triangular valve core, and the valve flap assembly opens momentarily, and the water supply side The water flows into the system side to replenish the spray pipe network. A small part of the water flows through the small holes on the seat ring to the retarder, the water motor alarm and the pressure switch. The water motor alarm emits a continuous alarm sound, and the pressure switch action will feedback the signal. To the fire control center, the fire control center controls the sound and light alarms together, and simultaneously starts the water supply pump to continuously supply water to achieve the purpose of automatic sprinkler and alarm.

3、Technical Support

|

Rated workingpressure |

1.6MPa |

||||

|

Seal test pressure |

3.2MPa |

||||

|

Connection method |

Groove (clamp) connection |

||||

|

Alarm performance test |

Inlet pressure |

0.14 MPa

|

System side flow |

15 L/min

|

No alarm |

|

0.14 MPa |

60 L/min |

Pressure switch operating |

|||

|

0.70 MPa |

80 L/min |

||||

|

1.20 MPa |

170 L/min |

||||

|

1.60 MPa |

170 L/min |

||||

|

Alarm port pressure |

0.14 MPa |

60 L/min |

≥0.05 MPa |

||

|

Delayer pressure test |

2 times rated working pressure, pressure for 5 min without deformation leakage |

||||

|

Alarm delay time |

5s~90s |

||||

|

Delayer automatic emptying time |

≤5 min |

||||

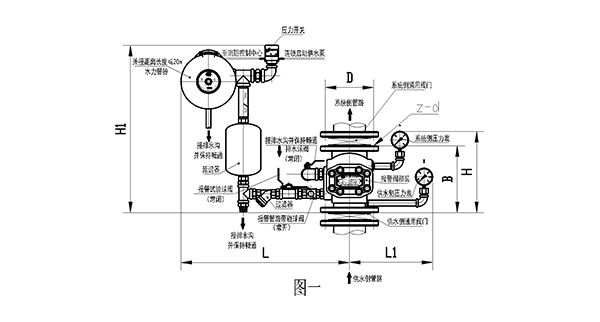

4、Connection size

|

Model |

DN |

D |

H1 |

H |

L1 |

L2 |

B |

|

ZSFZ 100(G-1.6MPa Groove Type) |

100 |

Φ114 |

517 |

445 |

167 |

416 |

254 |

|

ZSFZ 150(G-1.6MPa Groove Type) |

150 |

Φ165 |

525 |

453 |

194 |

434 |

281 |

|

ZSFZ 200(G-1.6MPa Groove Type) |

200 |

Φ219 |

525 |

461 |

277 |

455 |

352 |

|

ZSFZ 250(G-1.6MPa Groove Type) |

250 |

Φ273 |

550 |

472 |

300 |

510 |

370 |

Ruicheng Fire

Mobile Phone Version

Zhejiang Ruicheng Fire Equipment Co., Ltd.

Address: Binhai New City Industrial Park, Hairun Street, Sanmen County, Zhejiang Province

support hotline:

0576-83369588

0576-89330555

E-mail:

E-mail:[email protected]

All rights reserved:Zhejiang Ruicheng Fire Equipment Co., Ltd. Technical Support:HWAQ